PP hollow board is a kind of green environmental protection material. It is widely used in foreign countries. It has just begun in China and gradually replaces some corrugated packaging materials. Now some domestic enterprises are also developing and using it as building decoration materials! Because of its wide application and convenient use, PP hollow board is also widely used in Wantong board. It is widely used in advertising background, stationery materials, industrial packaging, product shockproof, etc. Our most common are turnover boxes, detachable combination boxes, finished packaging. Boxes and partitions in boxes, etc.

The hollow board is generally made of environmentally friendly and pollution-free retrievable thermoplastic polypropylene (PP), polyethylene (HDPE) resin and various excipients. In addition, there is a polycarbonate (PC) hollow board, also known as a sun board, glass cap. Long board, PC hollow board, is made of high-performance engineering plastic PC resin, with high transparency, light weight, impact resistance, sound insulation, heat insulation, flame retardant, anti-aging, etc. It is a high-tech, comprehensive The plastic plate with excellent performance, energy saving and environmental protection is the plastic building material commonly used in the world.

PP plastic hollow board is a new type of packaging material, which is produced by high temperature extrusion molding using PP pull pellets.

Hollow plastic building template features:

Non-toxic, tasteless;

Environmentally friendly and pollution-free;

Protect from moisture and corrosion;

Light weight, tensile strength, high strength and other properties;

The surface can be printed or pasted;

Different colors can be produced according to requirements;

By adding a flame retardant, the hollow board produced can reach the fire-extinguishing effect on the flame-retardant effect.

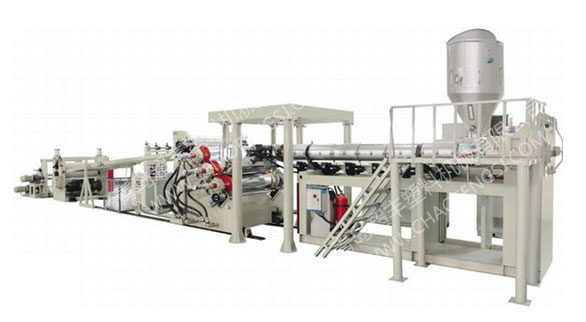

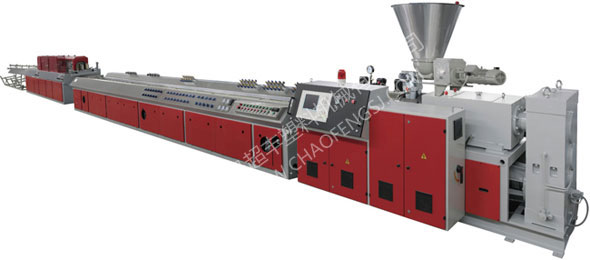

Hollow plastic building template production line introduction:

The hollow board production line is used for continuous production of grid plates in PC, PE and PP. Products are widely used in architectural decoration, advertising layout, road sound insulation for packaging. PE and PP grid plates can be used as packaging boxes instead of cardboard boxes, which are light in weight, high in strength, moisture-proof and anti-corrosive. Finished sheet width 1220-2100mm pp hollow grid board equipment, thickness 2-12mm.

1. Extruder: The special design of the screw and advanced temperature control system ensure the plasticization effect of the raw material is good and the high output is stable and extruded.

2. Screen changer: The hydraulic quick change screen device is adopted to make the screen change process fast and effective, the double station and the special sealing structure ensure the stable operation of the screen changer.

3. Mold: The mold is made of high-quality alloy steel with high-activity throttling device, so that the distribution pressure of the raw material flow in the die is uniform, and the upper and lower die are differentially adjusted to ensure uniform thickness of the upper and lower walls.

4. Vacuum setting table: There is a fast heat exchange refrigeration system in the shaping system. And the vacuum system is effectively staggered, the suction distribution is even and reasonable. Qingdao hollow grid plate equipment, this distribution ensures the setting accuracy. The vacuum system consists of two separate subsystems. Each subsystem is equipped with a plurality of three-point fixed-cycle vacuum groups, each of which carries a vacuum adjustment system and a vacuum display system to make the vacuum on the surface of the plate uniform and stable.

5. Traction machine: The tractor is distributed with a group and a second group. The traction machine of the group is high-power, large reduction ratio and multi-roller type. Its low-speed dynamic rotation performance is excellent, the traction force is large, and the plate can be pulled out from the vacuum setting table synchronously and evenly. The second group of tractors cooperates with the product stress. It is also equipped with a trimming device pvc hollow grid plate equipment to ensure the effective width and edge quality of the board.

6. Stress eliminator: Advanced large-area conduction heating method, which effectively eliminates the stress of the plate and further flatness of the plate.

Main applications of hollow grid panels:

● Widely used in electronics, home appliances, luggage, machinery, postal services, food, medicine, pesticides, advertising and decoration, etc.

●Lighting ceilings for office buildings, halls, shopping malls, stadiums, entertainment centers and public facilities

● Canopy for stations, parking lots, gazebos, and lounge corridors

●Safety lighting materials for airports and factories

●The sky of modern agriculture and aquaculture and indoor swimming pool

●Highway and urban elevated road noise barriers

● Road sign advertising, light box advertising and display exhibition layout

●Interior partition of office and private house, partition of shower room of family bathroom

Position:

Position:

![[product:P_title] [product:P_title]](/upLoad/product/month_1808/201808231552349232.jpg)